E

J

O

I

N

S

N

O

U

S

+91 09302834985

+91 09993530009

+91-788-2352148

+91-788-2286268

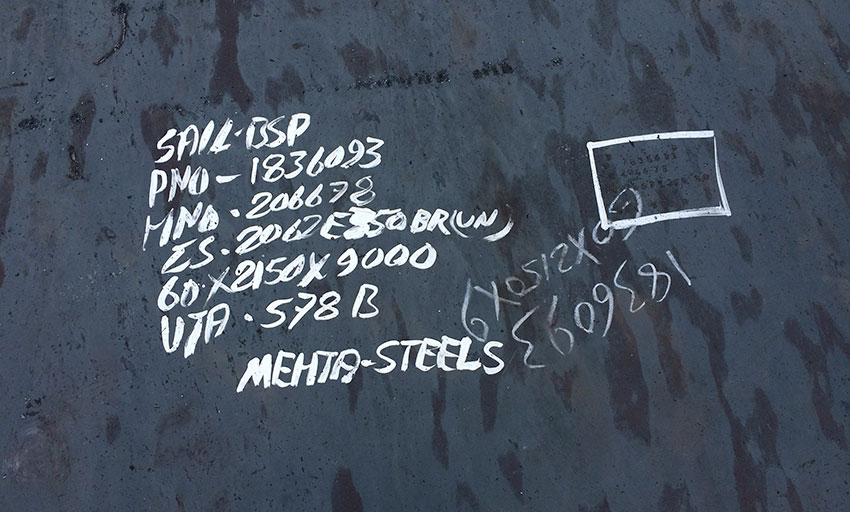

Mehta Steels 137, Light industrial area, Bhilai, Chattisgarh Pin- 490026, India.Plaques a haute resistance

Les plaques a haute resistance sont communement appelees plaques SAILMA en Inde ces plaques ht sont essentiellement des plaques capables de supporter une forte traction force. Les plaques ht sont classees en differentes qualites en fonction de leur limites d'elasticite.

En raison de ses plaques ht haute resistance, il permet de concevoir des produits et structures.

Mehta steels propose des plaques d'acier a haute resistance disponible dans diverses specifications

Plaques en acier a haute resistance

Utilisation et tableau des notes equivalentes des plaques HT

-

Description utileNorme IS Non et notePres Specification non SI equivalente

-

IS 2062 E 300 ASAILMA 300

-

IS 2062 E 300 CSAILMA 300 HI

-

IS 2062 E 350 ASAILMA 350

-

IS 2062 E 350 CSAILMA 350 HI

-

IS 2062 E 410 ASAILMA 410

-

IS 2062 E 410 CSAILMA 410 HI

-

IS 2062 E 450 ASAILMA 450

-

Lamine a chaud acier de construction moyenne haute resistanceIS 2062 E 450 BRSAILMA 450 HI

-

IS 2062 E 550 ASAILMA 550

-

IS 2062 E 550 BRSAILMA 550 HI

-

IS 2062 E 550 ASAIL HITEN

-

IS 2062 E 350 BREN 10025 S 355 JR

-

IS 2062 E 350 B0EN 10025 S 355 J0

-

IS 2062 E 350 CEN 10025 S 355 J2

-

IS 2062 E 350 CDIN 17100 ST 52.3

Condition technique de livraison obligatoire pour fourniture de plaques ht

TDC obligatoire pour la fourniture de plaques HT

| MANDATORY TECHNICAL DELIVERY CONDITIONS FOR HT PLATES | ||

| MANDATORY REQUIREMENTS FOR HIGH TENSILE GRADES | ||

| Nomenciature | Mandatory TDC As per Specification | Mandatory TDC As per Process requirement |

| IS 2062 E 300 A | TENSILE , BEND TEST (UP TO 25 MM) | Vaccum degassing for >= 32 mm Micro alloyed for all thickness |

| IS 2062 E 300 BR | TENSILE , BEND(UP TO 25 MM), (IMPACT OPTIONAL AT ROOM TEMP FOR >= 12 MM), | |

| IS 2062 E 300 B0 | TENSILE , BEND TEST(UP TO 25 MM) & IMPACT AT (0) DEG C FOR >= 12 MM | CR/NR/TCR for > 12 to <32 mm Normalised for >= 32 mm Vaccum degassing for >= 32 mmMicro alloyed for all thickness |

| IS 2062 E 300 C | TENSILE , BEND TEST(UP TO 25 MM) & IMPACT AT (-) 20 DEG C FOR >= 12 MM | |

| IS 2062 E 350 A | TENSILE , BEND TEST (UP TO 25 MM) | Vacuum degassing for >= 32 mm Micro alloyed for all thickness |

| IS 2062 E 350 BR | TENSILE , BEND(UP TO 25 MM), (IMPACT OPTIONAL AT ROOM TEMP FOR >= 12 MM) | |

| IS 2062 E 350 B0 | TENSILE , BEND TEST(UP TO 25 MM) & IMPACT AT (0) DEG C FOR >= 12 MM | CR/NR/TCR for > 12 to <32 mm Normalised for >= 32 mm Vaccum degassing for >= 32 mmMicro alloyed for all thickness |

| IS 2062 E 350 C | TENSILE , BEND TEST(UP TO 25 MM) & IMPACT AT (-) 20 DEG C FOR >= 12 MM | |

| IS 2062 E 410 A | TENSILE , BEND TEST (UP TO 25 MM) | Vacuum degassing for >= 28 mm Micro alloyed for all thickness |

| IS 2062 E 410 BR | TENSILE , BEND(UP TO 25 MM), (IMPACT OPTIONAL AT ROOM TEMP FOR >= 12 MM) | |

| IS 2062 E 410 B0 | TENSILE , BEND TEST(UP TO 25 MM) & IMPACT AT (0) DEG C FOR >= 12 MM | Normalised for >= 40 mm Vacuum degassing for >= 28 mm Micro alloyed for all thickness |

| IS 2062 E 410 C | TENSILE , BEND TEST(UP TO 25 MM) & IMPACT AT (-) 20 DEG C FOR >= 12 MM | |

| IS 2062 E 450 A | TENSILE , BEND TEST(UP TO 25 MM) | Vacuum degassing for all thickness Micro alloyed for all thickness |

| IS 2062 E 450 BR | TENSILE , BEND(UP TO 25 MM), (IMPACT OPTIONAL AT ROOM TEMP FOR >= 12 MM) | |

| IS 2062 E 550 A | TENSILE , BEND(UP TO 25 MM) | Vacuum degassing for all thickness Micro alloyed for all thickness Cu and Ni addition for all thickness |

| IS 2062 E 550 BR | TENSILE , BEND(UP TO 25 MM), IMPACT OPTIONAL AT ROOM TEMP. FOR >= 12 MM | |

| MANDATORY TECHNICAL DELIVERY CONDITIONS FOR HT PLATES | ||

| MANDATORY REQUIREMENTS FOR HIGH TENSILE PLATE GRADES | ||

| Nomenciature | Mandatory TDC As per Specification | Mandatory TDC As per Process requirement |

| IS 2062 E 300 A (MA 300) | TENSILE & BEND TEST | Vacuum degassing for >= 32 mm Micro alloyed for all thickness |

| IS 2062 E 300 BR (MA 300 HI) | TENSILE & BEND , IMPACT AT ROOM TEMP. FOR >= 12 MM | |

| IS 2062 E 300 B0 (MA 300 HI) | TENSILE + BEND TEST & IMPACT AT (0) DEG C FOR >= 12 MM | CR/NR/TCR for > 12 to <32 mm Normalised for >= 32 mm Vacuum degassing for >= 32 mm |

| IS 2062 E 300 C (MA 300 HI) | TENSILE + BEND TEST & IMPACT AT (-) 20 DEG C FOR >= 12 MM | |

| IS 2062 E 350 A (MA350) | TENSILE & BEND TEST | Vacuum degassing for >= 32 |

| IS 2062 E 350 BR (MA350 HI) | TENSILE & BEND , IMPACT AT ROOM TEMP. FOR >= 12 MM | |

| IS 2062 E 350 B0 (MA350 HI) | TENSILE + BEND TEST & IMPACT AT (0) DEG C FOR >= 12 MM | CR/NR/TCR for > 12 to <32 mm Normalised for >= 32 mm Vacuum degassing for >= 32 mm |

| IS 2062 E 350 C (MA350 HI) | TENSILE + BEND TEST & IMPACT AT (-) 20 DEG C FOR >= 12 MM | |

| IS 2062 E 410 A (MA410) | TENSILE + BEND TEST | Vacuum degassing for >= 28 mm |

| IS 2062 E 410 BR (MA410 HI) | TENSILE & BEND , IMPACT AT ROOM TEMP. FOR >= 12 MM | |

| IS 2062 E 410 B0 (MA410 HI) | TENSILE + BEND TEST & IMPACT AT (0) DEG C FOR >= 12 MM | Normalised for >= 40 mm Vacuum degassing for >= 28 mm |

| IS 2062 E 410 C (MA410 HI) | TENSILE + BEND TEST & IMPACT AT (-) 20 DEG C FOR >= 12 MM | |

| IS 2062 E 450 A (MA450) | TENSILE & BEND | Vacuum degassing for all thickness. |

| IS 2062 E450 BR (MA450 HI) | TENSILE , BEND , IMPACT AT ROOM TEMP. FOR >= 12 MM | |

| IS 2062 E 450 A (MA450 HI-B0) | TENSILE , BEND , IMPACT AT (0) DEG C. FOR >= 12 MM | Vacuum degassing for all

thickness. Normalised for >= 40 mm |

| IS 2062 E 450 A (MA450 HI-C) | TENSILE & BEND , IMPACT AT (-) 20 DEG C. FOR >= 12 MM | |

| IS 2062 E 550 A(MA550) | TENSILE & BEND TEST. | Vacuum Degassing for all

thickness. Cu and Ni addition for all thickness. |

| IS 2062 E 550 BR(MA550 HI) | TENSILE & BEND , IMPACT AT ROOM TEMP. FOR >= 12 MM | |

| IS 2062 E 550 A(MA550 HI-B0) | TENSILE & BEND , IMPACT AT (0) DEG C. FOR >= 12 MM | |

| IS 2062 E 550 A(MA550 HI-C) | TENSILE & BEND , IMPACT AT (-) 20 DEG C. FOR>=12 MM | |

French

French

Spanish

Spanish English

English