E

J

O

I

N

S

N

O

U

S

+91 09302834985

+91 09993530009

+91-788-2352148

+91-788-2286268

Mehta Steels 137, Light industrial area, Bhilai, Chattisgarh Pin- 490026, India.Canaux MS

Mehta aciers negocie et fournit des chaines MS selon Indian & amp; normes internationales.

Mehta steel est un fournisseur renomme de profiles en acier doux egalement connu comme ISMC fabrique par SAIL et re laminoirs.

Actionnaires de canaux en acier doux:

"Mehta steel" fournit des canaux legers et lourds en forme de "C" et autres profils importes tels que UPN , UPE , U chaines , PFC et norme americaine chaines etc.

ISMC fourni par «Mehta aciers» sont disponibles en acier doux et haute resistance ou ht grades. Dimensions communes des canaux MS disponibles en stock pret avec les «aciers Mehta» sommes:

-

Sr.No.DeccriptionSizeSection weight

(KG/Mtrs) -

1ISMC 7575 x 40 x 4.87.14

-

2ISMC 100100 x 50 x 59.56

-

3ISMC 125125 x 65 x 5.313.1

-

4ISMC 150150 x 75 x 5.716.8

-

5ISMC 175175 x 75 x 619.6

-

6ISMC 200200 x 75 x 6.222.3

-

7ISMC 250250 x 82 x 934.2

-

8ISMC 300300 x 90 x 7.836.3

-

9ISMC 350350 x 100 x 8.342.7

-

10ISMC 400400 x 100 x 8.850.1

Canaux de profil internationaux et importes: Mehta Steels est l'un des principaux fournisseurs de profils standard britanniques, europeens et americains de canaux en acier. Canaux selon les profils europeens:

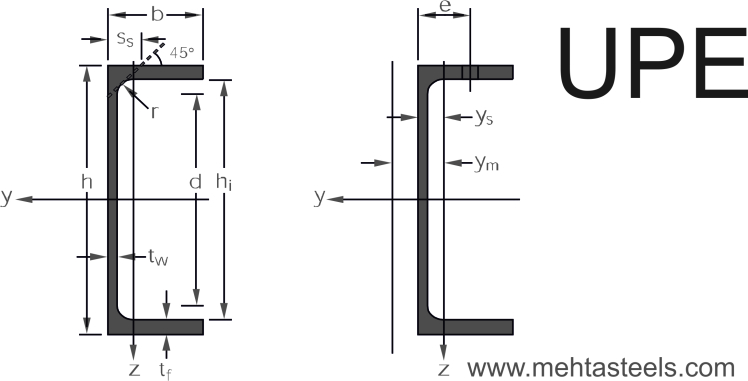

UPE

Profile en U mit parallelen Flanschen

Abmessungen: DIN 1026-2: 2002-10

Toleranzen: EN 10279: 2000

Oberflächenbeschaffenheit:

Gemäß EN 10163-3: 2004, Klasse C, Untergruppe 1

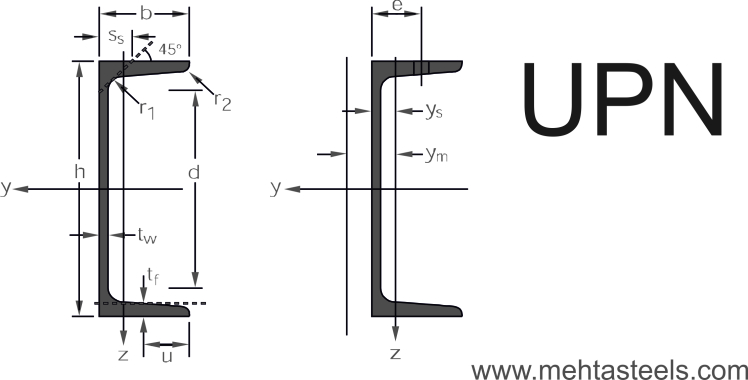

UPN

Chaines standards europeennes

Dimensions: DIN 1026-1: 2000, NF A 45-202: 1986

Tolerances: EN 10279: 2000

Etat de surface: selon EN 10163-3: 2004, class C, subclass 1

Profil U ou profil U

Canaux a brides coniques

Dimensions: conformement a la norme du moulin

Tolerances: EN 10279: 2000

Oberflächenbeschaffenheit:

etat de surface: selon to EN 10163-3: 2004, class C, subclass 1

Canaux selon les profils britanniques:

PFC

Canaux a brides paralleles britanniques

Dimensions: BS 4-1: 2005

Tolerances: EN 10279: 2000

etat de surface: selon to EN 10163-3: 2004,class C, subclass 1

Chaines

Canaux britanniques a brides coniques

Dimensions: Conforme a l'ancienne BS 4-1: 1993

Tolerances: EN 10279: 2000

etat de surface: selon EN 10163-3: 2004, class C, subclass 1

Canaux selon les normes americaines:

C

Chaines standards americaines

Pente de la bride: env. 162/3%

Dimensions: ASTM A 6 / A 6M & # 8211; 07

Tolerances: ASTM A 6 / A 6M & # 8211; 07

etat de surface: selon ASTM A 6/A 6M – 07

MC

Chaines americaines

Dimensions: ASTM A 6/A 6M – 07

Tolerances: ASTM A 6/A 6M – 07

Surface condition: according to ASTM A 6/A 6M – 07

Chaines selon les normes russes:

UE

Canaux a brides coniques

Dimensions: GOST 8240-97; PN-H-93451

Tolerances: GOST 8240-97; EN 10279: 2000

Surface condition: according to EN 10163-3: 2004, class C, subclass 1

Chaines standard europeennes

Dimensions: DIN 1026-1: 2000, NF A

45-202: 1986

Dimensions: DIN 1026-1: 2000, NF A

45-202: 1986

Tolerances: EN 10279: 2000

Surface condition: according to EN 10163-3: 2004, class C,

subclass 1

| Item | G | h | b | tw | tf | r1 | r2 | A | d | Ø | emin | emax | AL | AG |

| kg/m | mm | mm | mm | mm | mm | mm | mm2 | mm | mm | mm | m2/m | m2/t | ||

| UPN 80* | 8.64 | 80 | 45 | 6.0 | 8.0 | 8.0 | 4.0 | 11.0 | 47 | – | – | – | 0.312 | 37.10 |

| UPN 100* | 10.6 | 100 | 50 | 6.0 | 8.5 | 8.5 | 4.5 | 13.5 | 64 | – | – | – | 0.372 | 35.10 |

| UPN 120 | 13.4 | 120 | 55 | 7.0 | 9.0 | 9.0 | 4.5 | 17.0 | 82 | – | – | – | 0.434 | 32.52 |

| UPN 140 | 16.0 | 140 | 60 | 7.0 | 10.0 | 10.0 | 5.0 | 20.4 | 98 | M 12 | 33 | 37 | 0.489 | 30.54 |

| UPN 160 | 18.8 | 160 | 65 | 7.5 | 10.5 | 10.5 | 5.5 | 24.0 | 115 | M 12 | 34 | 42 | 0.546 | 28.98 |

| UPN 180 | 22.0 | 180 | 70 | 8.0 | 11.0 | 11.0 | 5.5 | 28.0 | 133 | M 16 | 38 | 41 | 0.611 | 27.80 |

| UPN 200 | 25.3 | 200 | 75 | 8.5 | 11.5 | 11.5 | 6.0 | 32.2 | 151 | M 16 | 39 | 46 | 0.661 | 26.15 |

| UPN 220 | 29.4 | 220 | 80 | 9.0 | 12.5 | 12.5 | 6.5 | 37.4 | 167 | M 16 | 40 | 51 | 0.718 | 24.46 |

| UPN 240 | 33.2 | 240 | 85 | 9.5 | 13.0 | 13.0 | >6.5 | >42.3 | 184 | M 20 | 46 | 50 | 0.775 | 23.34 |

| UPN 260 | 37.9 | 260 | 90 | 10.0 | 14.0 | 14.0 | 7.0 | 48.3 | 200 | M 22 | 50 | 52 | 0.834 | 22.00 |

| UPN 280 | 41.8 | 280 | 95 | 10.0 | 15.0 | 15.0 | 7.5 | 53.3 | 216 | M 22 | 52 | 57 | 0.890 | 21.27 |

| UPN 300 | 46.2 | 300 | 100 | 10.0 | 16.0 | 16.0 | 8.0 | 58.8 | 232 | M 24 | 55 | 59 | 0.950 | 20.58 |

| UPN 320* | 59.5 | 320 | 100 | 14.0 | 17.5 | 17.5 | 8.8 | 75.8 | 246 | M 22 | 58 | 62 | 0.982 | 16.50 |

| UPN 350 | 60.6 | 350 | 100 | 14.0 | 16.0 | 16.0 | 8.0 | 77.3 | 282 | M 22 | 56 | 62 | 1.05 | 17.25 |

| UPN 380* | 63.1 | 380 | 102 | 13.5 | 16.0 | 16.0 | 8.0 | 80.4 | 313 | M 24 | 59 | 60 | 1.11 | 17.59 |

| UPN 400* | 71.8 | 400 | 110 | 14.0 | 18.0 | 18.0 | 9.0 | 91.5 | 324 | M 27 | 61 | 62 | 1.18 | 16.46 |

* Minimum tonnage and delivery conditions upon agreement.

| h≤300 | h>300 |

| u | b/2 | b-tw/2 |

| Flange slope | 8% | 5% |

Canaux a brides paralleles

Dimensions: DIN 1026-2: 2002-10

Dimensions: DIN 1026-2: 2002-10

Tolerances: EN 10279: 2000

Surface condition: according to EN 10163-3: 2004, class C,

subclass 1

| Item | G | h | b | tw | tf | r | A | hi | d | Ø | emin | emax | AL | AG |

| kg/m | mm | mm | mm | mm | mm | mm2 | mm | mm | mm | mm | m2/m | m2/t | ||

| x102 | ||||||||||||||

| UPE 80* | 7.90 | 80 | 50 | 4.0 | 7.0 | 10 | 10.1 | 66 | 46 | – | – | – | 0.343 | 43.45 |

| UPE 100* | 9.82 | 100 | 55 | 4.5 | 7.5 | 10 | 12.5 | 85 | 65 | M 12 | 35 | 36 | 0.402 | 41.00 |

| UPE 120* | 12.1 | 120 | 60 | 5.0 | 8.0 | 12 | 15.4 | 104 | 80 | M 12 | 35 | 41 | 0.460 | 37.98 |

| UPE 140* | 14.5 | 140 | 65 | 5.0 | 9.0 | 12 | 18.4 | 122 | 98 | M 16 | 35 | 38 | 0.520 | 35.95 |

| UPE 160* | 17.0 | 160 | 70 | 5.5 | 9.5 | 12 | 21.7 | 141 | 117 | M 16 | 36 | 43 | 0.579 | 34.01 |

| UPE 180* | 19.7 | 180 | 75 | 5.5 | 10.5 | 12 | 25.1 | 159 | 135 | M 16 | 36 | 48 | 0.639 | 32.40 |

| UPE 200* | 22.8 | 200 | 80 | 6.0 | 11.0 | 13 | 29.0 | 178 | 152 | M 20 | 46 | 47 | 0.697 | 30.60 |

| UPE 220* | 26.6 | 220 | 85 | 6.5 | 12.0 | 13 | 33.9 | 196 | 170 | M 22 | 47 | 49 | 0.756 | 28.43 |

| UPE 240* | 30.2 | 240 | 90 | 7.0 | 12.5 | 15 | 38.5 | 215 | 185 | M 24 | 47 | 51 | 0.813 | 26.89 |

| UPE 270* | 35.2 | 270 | 95 | 7.5 | 13.5 | 15 | 44.8 | 243 | 213 | M 27 | 48 | 50 | 0.892 | 25.34 |

| UPE 300* | 44.4 | 300 | 100 | 9.5 | 15.0 | 15 | 56.6 | 270 | 240 | M 27 | 50 | 55 | 0.968 | 21.78 |

| UPE 330* | 53.2 | 330 | 105 | 11.0 | 16.0 | 18 | 67.8 | 298 | 262 | M 27 | 54 | 60 | 1.043 | 19.60 |

| UPE 360* | 61.2 | 360 | 110 | 12.0 | 17.0 | 18 | 77.9 | 326 | 290 | M 27 | 55 | 65 | 1.121 | 18.32 |

| UPE 400* | 72.2 | 400 | 115 | 13.5 | 18.0 | 18 | 91.9 | 364 | 328 | M 27 | 57 | 70 | 1.218 | 16.87 |

French

French

Spanish

Spanish English

English