e

a

c

h

U

s

+91 09302834985

+91 09993530009

+91-788-2352148

+91-788-2286268

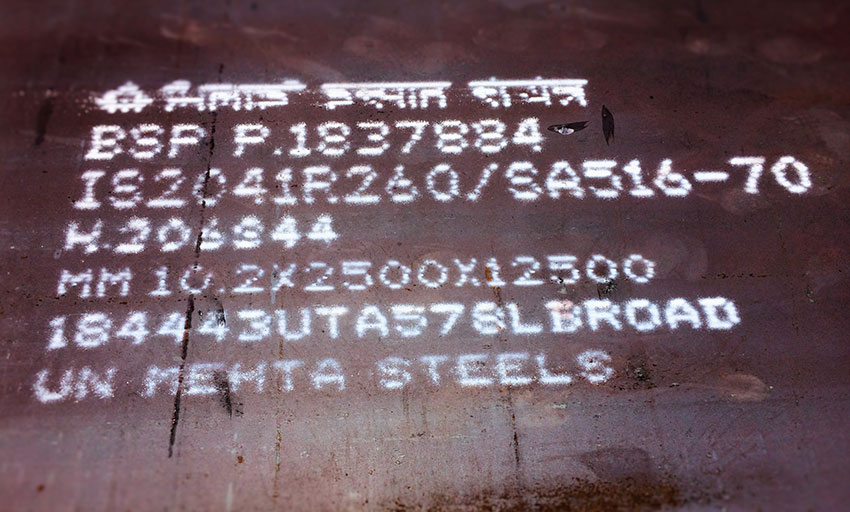

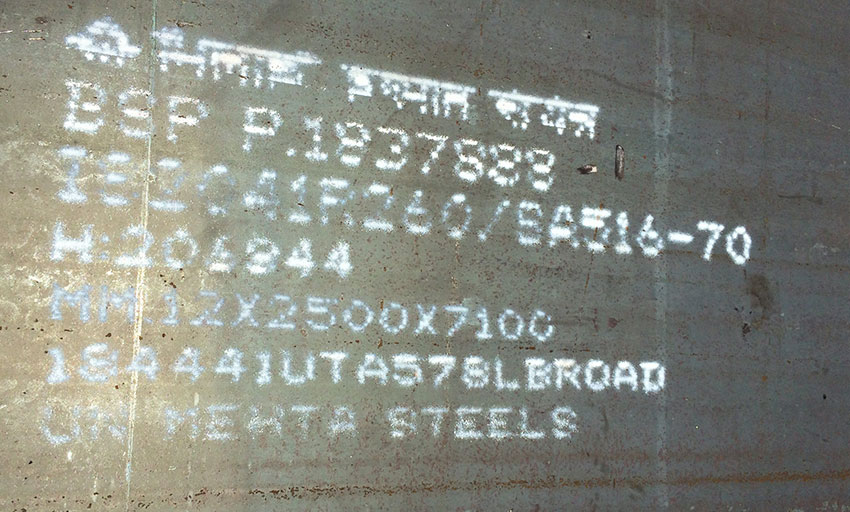

Mehta Steels 137, Light industrial area, Bhilai, Chattisgarh Pin- 490026, India.Boiler quality plates

Mehta steels the stockholder of bq plates:

Boiler quality plates also most commonly called as boiler grade plates are those mild steel plates with chemical composition and mechanical properties that make these bq plates capable of withstanding high temperatures and heavy pressure. Boiler plates are used in various high temperature applications such as steam boilers , boilers made of mild steel , pressure vessels , pen stock pipes , LPG bullets , are some of the examples.

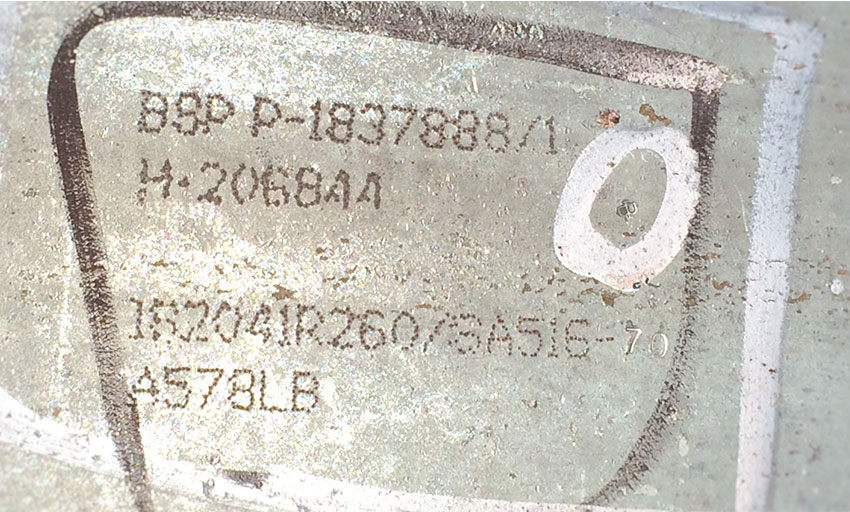

Mehta steels is stockiest of bq plates tested as per Indian standard IS 2002 GR.II , IS 2002 Gr.III , IS 2041 R 220 , IS 2041 R 260.

Some of the common grades which are available readily in stock are IS 2002 Gr.II and ASTM A 516 Gr.70 equivalent grade IS 2041 R 260.

Common sizes of b.q.plates readily available in stock with Mehta steels are:

-

THICK (mm)WIDTH (mm)LENGTH (mm)

-

615006300

-

815006300

-

1015006300

-

10.2250012500

-

12250012500

-

14250012500

-

16250012500

-

18250012500

-

20250012500

-

22250012500

-

25250012500

-

28250012500

-

30250012500

-

32250012500

-

36250012500

-

40250012500

-

45250010000

-

50250010000

-

6325006300

-

7025006300

-

7525006300

-

8025005000

-

9025005000

-

10025005000

Common grades of boiler quality plates in stock with Mehta steels are:

- IS 2002-1 or IS 2002 Gr. I

- IS 2002-2 or IS 2002 Gr. II

- IS 2002-3 or IS 2002 Gr. III

- IS 2041R220

- IS 2041R260

- IS 2041R355

Pressure vessels quality plates and boiler quality plates :

Use and equivalent grade chart of bq plates

-

Description of useIS standard No and gradeNear Equivalent Non IS Specification

-

IS 2002 Grade 1ASTM/ASME 515 Gr.60

-

For intermediate and

high temperatureIS 2002 Grade 2ASTM/ASME 515 Gr.65 -

IS 2002 Grade 3ASTM/ASME 515 Gr.70

-

IS 2041 Grade R 220ASTM/ASME 516 Gr.55

-

IS 2041 Grade R 220ASTM/ASME 516 Gr.60

-

IS 2041 Grade R 260ASTM/ASME 516 Gr.65

-

IS 2041 Grade R 260ASTM/ASME 516 Gr.70

-

For moderate & low temperatureIS 2041 Grade R 355ASTM/ASME 537 Class 1

-

IS 2041 Grade H 235DIN 17155 Gr HI

-

IS 2041 Grade H 235EN 10028-P2-P235GH

-

IS 2041 Grade H 265EN 10028-P2-P265GH

-

IS 2041 Grade H 295EN 10028-P2-P295GH

-

IS 2041 Grade H 355EN 10028-P2-P355GH

HS code for hot rolled flat steel products

Mandatory tdc for supply of bq plates

| MANDATORY TECHNICAL DELIVERY CONDITIONS FOR BQ PLATES | ||

| MANDATORY REQUIREMENTS FOR BOILER QUALITY GRADES | ||

| Nomenclature | Mandatory TDC As per Specification | Mandatory TDC As per Process requirement |

| IS 2002-1 | Normalized for >= 12 mm Tensile test + Bend test |

Vacuum degassing for >= 40 mm Above 40 mm, thickness tolerance as per mutual agreement. |

| IS 2002-2 | ||

| IS 2002-3 | ||

| IS 2041R220 | Fine grain Practice (AI 0.02 min in

ladle) Normalised for > 12 mm Normalized for all thick when impact tested Tensile test |

Vacuum degassing for >= 40 mm Vacuum degassing and micro alloy for all thickness – when impact test is lower than (-) 20*C – Impact (Transverse) for any temperature. |

| IS 2041R260 | ||

| IS 2041R355 | Fine grain Practice (AI 0.02 min in ladle) Normalized for all thickness Tensile test + Impact test at any one temperature of +20/0/-20/-40 |

Vacuum degassing and micro alloy For all thickness |

| MANDATORY TECHNICAL DELIVERY CONDITIONS FOR BQ PLATES | ||

| MANDATORY REQUIREMENTS FOR BOILER QUALITY GRADES | ||

| Nomenclature | Mandatory TDC As per Specification | Mandatory TDC As per Process requirement |

| IS 2041R220/A285C | Fine grain Practice (AI 0.02 min in

ladle) Tensile test Normalized for > 12 mm Normalized for all thick when impact tested |

Vacuum degassing for >= 40 mm |

| IS 2041R220/SA285C | ||

| IS 2002-1/A515-60 | Normalized for > 12 mm Tensile test + Bend test |

Vacuum degassing for >= 40 mm |

| IS 2002-1/SA515-60 | ||

| IS 2002-2/A515-65 | ||

| IS 2002-2/SA515-65 | ||

| IS 2002-3/A515-70 | ||

| IS 2002-3/SA515-70 | ||

| IS 2041R220/A516-55 | Fine grain Practice (AI 0.02 min in

ladle) Normalized for > 12 mm Normalized for all thick when impact tested Tensile test |

Vacuum degassing for >= 40 mm Vacuum degassing and micro alloy for all thickness – when impact test is lower than (-) 20*C -Impact (Transverse) for any temperature. |

| IS 2041R220/SA516-55 | ||

| IS 2041R220/A516-60 | ||

| IS 2041R220/SA516-60 | ||

| IS 2041R260/A516-65 | ||

| IS 2041R260/SA516-65 | ||

| IS 2041R260/A516-70 | ||

| IS 2041R260/SA516-70 | ||

| IS 2041R355/A537CL1 | Fine grain Practice (AI 0.02 min in

ladle) Normalized for all thickness Tensile test + Impact test at any one temperature of +20/0/-20/-40 |

Vacuum degassing and micro alloy For all thickness. |

| IS 2041R355/SA537CL1 | ||

English

English

Spanish

Spanish French

French