e

a

c

h

U

s

+91 09302834985

+91 09993530009

+91-788-2352148

+91-788-2286268

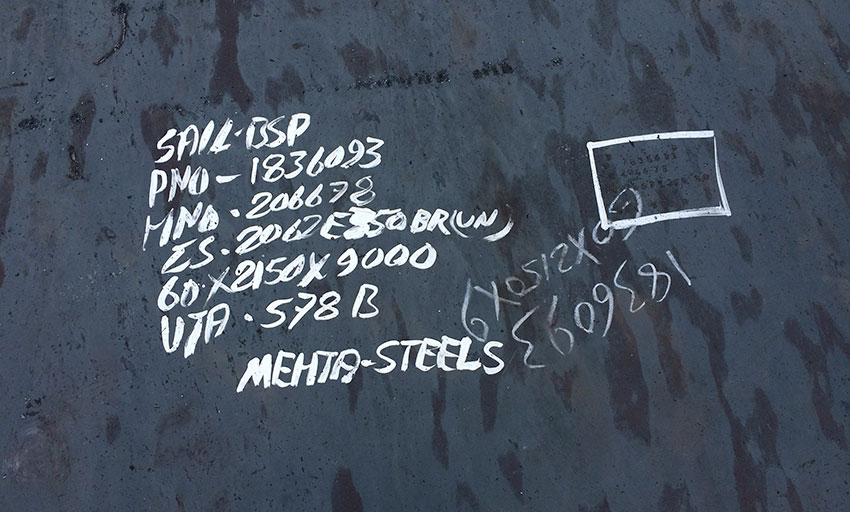

Mehta Steels 137, Light industrial area, Bhilai, Chattisgarh Pin- 490026, India.High Tensile Plates

High tensile plates are commonly known as SAILMA plates in India this ht plates are basically plates capable of bearing high tensile strength. ht plates are categorized in different grades based on their yield strengths.

Due to its high strength ht plates enables design of lighter, more durable and efficient products and structures.

Mehta steels is engaged in offering high tensile steel plates available in various specifications

High tensile steel plates

Use and equivalent grade chart of ht plates

-

Description of useIS standard No and gradeNear Equivalent Non IS Specification

-

IS 2062 E 300 ASAILMA 300

-

IS 2062 E 300 CSAILMA 300 HI

-

IS 2062 E 350 ASAILMA 350

-

IS 2062 E 350 CSAILMA 350 HI

-

IS 2062 E 410 ASAILMA 410

-

IS 2062 E 410 CSAILMA 410 HI

-

IS 2062 E 450 ASAILMA 450

-

Hot rolled medium high tensile structural steelIS 2062 E 450 BRSAILMA 450 HI

-

IS 2062 E 550 ASAILMA 550

-

IS 2062 E 550 BRSAILMA 550 HI

-

IS 2062 E 550 ASAIL HITEN

-

IS 2062 E 350 BREN 10025 S 355 JR

-

IS 2062 E 350 B0EN 10025 S 355 J0

-

IS 2062 E 350 CEN 10025 S 355 J2

-

IS 2062 E 350 CDIN 17100 ST 52.3

Mandatory technical delivery condition for supply of ht plates

Mandatory tdc for supply of ht plates

| MANDATORY TECHNICAL DELIVERY CONDITIONS FOR HT PLATES | ||

| MANDATORY REQUIREMENTS FOR HIGH TENSILE GRADES | ||

| Nomenciature | Mandatory TDC As per Specification | Mandatory TDC As per Process requirement |

| IS 2062 E 300 A | TENSILE , BEND TEST (UP TO 25 MM) | Vaccum degassing for >= 32 mm Micro alloyed for all thickness |

| IS 2062 E 300 BR | TENSILE , BEND(UP TO 25 MM), (IMPACT OPTIONAL AT ROOM TEMP FOR >= 12 MM), | |

| IS 2062 E 300 B0 | TENSILE , BEND TEST(UP TO 25 MM) & IMPACT AT (0) DEG C FOR >= 12 MM | CR/NR/TCR for > 12 to <32 mm Normalised for >= 32 mm Vaccum degassing for >= 32 mmMicro alloyed for all thickness |

| IS 2062 E 300 C | TENSILE , BEND TEST(UP TO 25 MM) & IMPACT AT (-) 20 DEG C FOR >= 12 MM | |

| IS 2062 E 350 A | TENSILE , BEND TEST (UP TO 25 MM) | Vacuum degassing for >= 32 mm Micro alloyed for all thickness |

| IS 2062 E 350 BR | TENSILE , BEND(UP TO 25 MM), (IMPACT OPTIONAL AT ROOM TEMP FOR >= 12 MM) | |

| IS 2062 E 350 B0 | TENSILE , BEND TEST(UP TO 25 MM) & IMPACT AT (0) DEG C FOR >= 12 MM | CR/NR/TCR for > 12 to <32 mm Normalised for >= 32 mm Vaccum degassing for >= 32 mmMicro alloyed for all thickness |

| IS 2062 E 350 C | TENSILE , BEND TEST(UP TO 25 MM) & IMPACT AT (-) 20 DEG C FOR >= 12 MM | |

| IS 2062 E 410 A | TENSILE , BEND TEST (UP TO 25 MM) | Vacuum degassing for >= 28 mm Micro alloyed for all thickness |

| IS 2062 E 410 BR | TENSILE , BEND(UP TO 25 MM), (IMPACT OPTIONAL AT ROOM TEMP FOR >= 12 MM) | |

| IS 2062 E 410 B0 | TENSILE , BEND TEST(UP TO 25 MM) & IMPACT AT (0) DEG C FOR >= 12 MM | Normalised for >= 40 mm Vacuum degassing for >= 28 mm Micro alloyed for all thickness |

| IS 2062 E 410 C | TENSILE , BEND TEST(UP TO 25 MM) & IMPACT AT (-) 20 DEG C FOR >= 12 MM | |

| IS 2062 E 450 A | TENSILE , BEND TEST(UP TO 25 MM) | Vacuum degassing for all thickness Micro alloyed for all thickness |

| IS 2062 E 450 BR | TENSILE , BEND(UP TO 25 MM), (IMPACT OPTIONAL AT ROOM TEMP FOR >= 12 MM) | |

| IS 2062 E 550 A | TENSILE , BEND(UP TO 25 MM) | Vacuum degassing for all thickness Micro alloyed for all thickness Cu and Ni addition for all thickness |

| IS 2062 E 550 BR | TENSILE , BEND(UP TO 25 MM), IMPACT OPTIONAL AT ROOM TEMP. FOR >= 12 MM | |

| MANDATORY TECHNICAL DELIVERY CONDITIONS FOR HT PLATES | ||

| MANDATORY REQUIREMENTS FOR HIGH TENSILE PLATE GRADES | ||

| Nomenciature | Mandatory TDC As per Specification | Mandatory TDC As per Process requirement |

| IS 2062 E 300 A (MA 300) | TENSILE & BEND TEST | Vacuum degassing for >= 32 mm Micro alloyed for all thickness |

| IS 2062 E 300 BR (MA 300 HI) | TENSILE & BEND , IMPACT AT ROOM TEMP. FOR >= 12 MM | |

| IS 2062 E 300 B0 (MA 300 HI) | TENSILE + BEND TEST & IMPACT AT (0) DEG C FOR >= 12 MM | CR/NR/TCR for > 12 to <32 mm Normalised for >= 32 mm Vacuum degassing for >= 32 mm |

| IS 2062 E 300 C (MA 300 HI) | TENSILE + BEND TEST & IMPACT AT (-) 20 DEG C FOR >= 12 MM | |

| IS 2062 E 350 A (MA350) | TENSILE & BEND TEST | Vacuum degassing for >= 32 |

| IS 2062 E 350 BR (MA350 HI) | TENSILE & BEND , IMPACT AT ROOM TEMP. FOR >= 12 MM | |

| IS 2062 E 350 B0 (MA350 HI) | TENSILE + BEND TEST & IMPACT AT (0) DEG C FOR >= 12 MM | CR/NR/TCR for > 12 to <32 mm Normalised for >= 32 mm Vacuum degassing for >= 32 mm |

| IS 2062 E 350 C (MA350 HI) | TENSILE + BEND TEST & IMPACT AT (-) 20 DEG C FOR >= 12 MM | |

| IS 2062 E 410 A (MA410) | TENSILE + BEND TEST | Vacuum degassing for >= 28 mm |

| IS 2062 E 410 BR (MA410 HI) | TENSILE & BEND , IMPACT AT ROOM TEMP. FOR >= 12 MM | |

| IS 2062 E 410 B0 (MA410 HI) | TENSILE + BEND TEST & IMPACT AT (0) DEG C FOR >= 12 MM | Normalised for >= 40 mm Vacuum degassing for >= 28 mm |

| IS 2062 E 410 C (MA410 HI) | TENSILE + BEND TEST & IMPACT AT (-) 20 DEG C FOR >= 12 MM | |

| IS 2062 E 450 A (MA450) | TENSILE & BEND | Vacuum degassing for all thickness. |

| IS 2062 E450 BR (MA450 HI) | TENSILE , BEND , IMPACT AT ROOM TEMP. FOR >= 12 MM | |

| IS 2062 E 450 A (MA450 HI-B0) | TENSILE , BEND , IMPACT AT (0) DEG C. FOR >= 12 MM | Vacuum degassing for all

thickness. Normalised for >= 40 mm |

| IS 2062 E 450 A (MA450 HI-C) | TENSILE & BEND , IMPACT AT (-) 20 DEG C. FOR >= 12 MM | |

| IS 2062 E 550 A(MA550) | TENSILE & BEND TEST. | Vacuum Degassing for all

thickness. Cu and Ni addition for all thickness. |

| IS 2062 E 550 BR(MA550 HI) | TENSILE & BEND , IMPACT AT ROOM TEMP. FOR >= 12 MM | |

| IS 2062 E 550 A(MA550 HI-B0) | TENSILE & BEND , IMPACT AT (0) DEG C. FOR >= 12 MM | |

| IS 2062 E 550 A(MA550 HI-C) | TENSILE & BEND , IMPACT AT (-) 20 DEG C. FOR>=12 MM | |

English

English

Spanish

Spanish French

French