e

a

c

h

U

s

+91 09302834985

+91 09993530009

+91-788-2352148

+91-788-2286268

Mehta Steels 137, Light industrial area, Bhilai, Chattisgarh Pin- 490026, India.MS Channels

Mehta steels trades and supplies ms channels as per Indian & international standards.

Mehta steels is a renowned suppliers of mild steel channels also known as ISMC manufactured by SAIL and re rolling mills.

Stockholders of mild steel channels:

‘Mehta steels’ supplies ‘C’ shape light and heavy channels and other imported profiles like UPN , UPE , U channels , PFC and American standard channels etc.

ISMC supplied by ‘Mehta steels’ are available in mild steel and high tensile or ht grades. Common dimensions of ms channels available in ready stock with ‘Mehta steels’ are:

-

Sr.No.DeccriptionSizeSection weight

(KG/Mtrs) -

1ISMC 7575 x 40 x 4.87.14

-

2ISMC 100100 x 50 x 59.56

-

3ISMC 125125 x 65 x 5.313.1

-

4ISMC 150150 x 75 x 5.716.8

-

5ISMC 175175 x 75 x 619.6

-

6ISMC 200200 x 75 x 6.222.3

-

7ISMC 250250 x 82 x 934.2

-

8ISMC 300300 x 90 x 7.836.3

-

9ISMC 350350 x 100 x 8.342.7

-

10ISMC 400400 x 100 x 8.850.1

International and Imported profile Channels: Mehta Steels is a key suppliers of British , European and American standard profiles of mild steel channels. Channels as per European profiles:

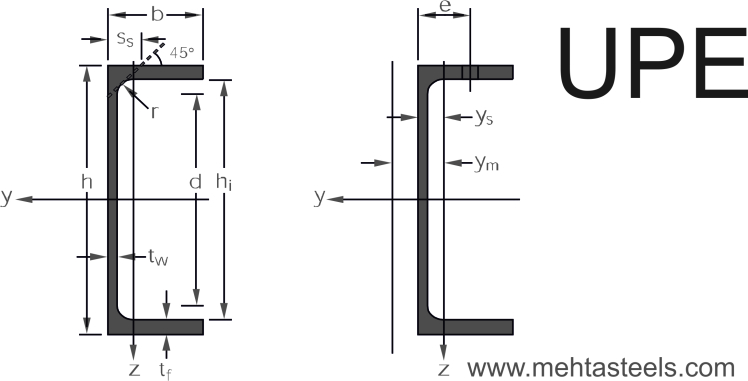

UPE

U-Profile mit parallelen Flanschen

Abmessungen: DIN 1026-2: 2002-10

Toleranzen: EN 10279: 2000

Oberflächenbeschaffenheit:

Gemäß EN 10163-3: 2004, Klasse C, Untergruppe 1

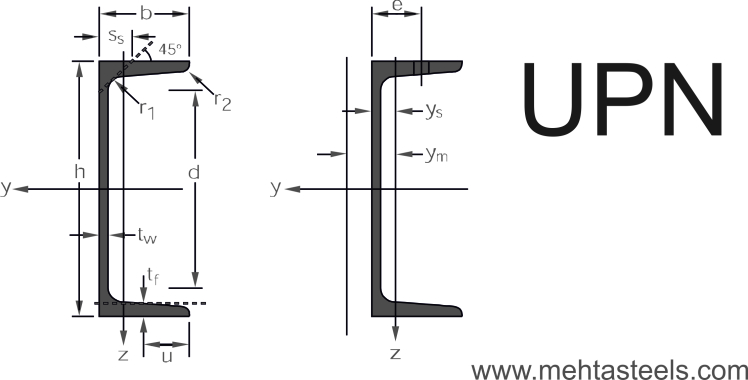

UPN

European standard channels

Dimensions: DIN 1026-1: 2000, NF A 45-202: 1986

Tolerances: EN 10279: 2000

Surface condition: according to EN 10163-3: 2004, class C, subclass 1

U Channel or U profile

Channels with taper flanges

Dimensions: in accordance with mill standard

Tolerances: EN 10279: 2000

Oberflächenbeschaffenheit:

Surface condition: according to EN 10163-3: 2004, class C, subclass 1

Channels as per British profiles:

PFC

British parallel flange channels

Dimensions: BS 4-1: 2005

Tolerances: EN 10279: 2000

Surface condition: according to EN 10163-3: 2004,class C, subclass 1

Channels

British channels with taper flanges

Dimensions: In accordance with former BS 4-1: 1993

Tolerances: EN 10279: 2000

Surface condition: according to EN 10163-3: 2004, class C, subclass 1

Channels as per American standards:

C

American standard channels

Flange slope: approx. 162/3 %

Dimensions: ASTM A 6/A 6M – 07

Tolerances: ASTM A 6/A 6M – 07

Surface condition: according to ASTM A 6/A 6M – 07

MC

American Channels

Dimensions: ASTM A 6/A 6M – 07

Tolerances: ASTM A 6/A 6M – 07

Surface condition: according to ASTM A 6/A 6M – 07

Channels as per Russian standards:

UE

Channels with taper flanges

Dimensions: GOST 8240-97; PN-H-93451

Tolerances: GOST 8240-97; EN 10279: 2000

Surface condition: according to EN 10163-3: 2004, class C, subclass 1

European standard channels

Dimensions: DIN 1026-1: 2000, NF A

45-202: 1986

Dimensions: DIN 1026-1: 2000, NF A

45-202: 1986

Tolerances: EN 10279: 2000

Surface condition: according to EN 10163-3: 2004, class C,

subclass 1

| Item | G | h | b | tw | tf | r1 | r2 | A | d | Ø | emin | emax | AL | AG |

| kg/m | mm | mm | mm | mm | mm | mm | mm2 | mm | mm | mm | m2/m | m2/t | ||

| UPN 80* | 8.64 | 80 | 45 | 6.0 | 8.0 | 8.0 | 4.0 | 11.0 | 47 | – | – | – | 0.312 | 37.10 |

| UPN 100* | 10.6 | 100 | 50 | 6.0 | 8.5 | 8.5 | 4.5 | 13.5 | 64 | – | – | – | 0.372 | 35.10 |

| UPN 120 | 13.4 | 120 | 55 | 7.0 | 9.0 | 9.0 | 4.5 | 17.0 | 82 | – | – | – | 0.434 | 32.52 |

| UPN 140 | 16.0 | 140 | 60 | 7.0 | 10.0 | 10.0 | 5.0 | 20.4 | 98 | M 12 | 33 | 37 | 0.489 | 30.54 |

| UPN 160 | 18.8 | 160 | 65 | 7.5 | 10.5 | 10.5 | 5.5 | 24.0 | 115 | M 12 | 34 | 42 | 0.546 | 28.98 |

| UPN 180 | 22.0 | 180 | 70 | 8.0 | 11.0 | 11.0 | 5.5 | 28.0 | 133 | M 16 | 38 | 41 | 0.611 | 27.80 |

| UPN 200 | 25.3 | 200 | 75 | 8.5 | 11.5 | 11.5 | 6.0 | 32.2 | 151 | M 16 | 39 | 46 | 0.661 | 26.15 |

| UPN 220 | 29.4 | 220 | 80 | 9.0 | 12.5 | 12.5 | 6.5 | 37.4 | 167 | M 16 | 40 | 51 | 0.718 | 24.46 |

| UPN 240 | 33.2 | 240 | 85 | 9.5 | 13.0 | 13.0 | >6.5 | >42.3 | 184 | M 20 | 46 | 50 | 0.775 | 23.34 |

| UPN 260 | 37.9 | 260 | 90 | 10.0 | 14.0 | 14.0 | 7.0 | 48.3 | 200 | M 22 | 50 | 52 | 0.834 | 22.00 |

| UPN 280 | 41.8 | 280 | 95 | 10.0 | 15.0 | 15.0 | 7.5 | 53.3 | 216 | M 22 | 52 | 57 | 0.890 | 21.27 |

| UPN 300 | 46.2 | 300 | 100 | 10.0 | 16.0 | 16.0 | 8.0 | 58.8 | 232 | M 24 | 55 | 59 | 0.950 | 20.58 |

| UPN 320* | 59.5 | 320 | 100 | 14.0 | 17.5 | 17.5 | 8.8 | 75.8 | 246 | M 22 | 58 | 62 | 0.982 | 16.50 |

| UPN 350 | 60.6 | 350 | 100 | 14.0 | 16.0 | 16.0 | 8.0 | 77.3 | 282 | M 22 | 56 | 62 | 1.05 | 17.25 |

| UPN 380* | 63.1 | 380 | 102 | 13.5 | 16.0 | 16.0 | 8.0 | 80.4 | 313 | M 24 | 59 | 60 | 1.11 | 17.59 |

| UPN 400* | 71.8 | 400 | 110 | 14.0 | 18.0 | 18.0 | 9.0 | 91.5 | 324 | M 27 | 61 | 62 | 1.18 | 16.46 |

* Minimum tonnage and delivery conditions upon agreement.

| h≤300 | h>300 |

| u | b/2 | b-tw/2 |

| Flange slope | 8% | 5% |

Channels with parallel flanges

Dimensions: DIN 1026-2: 2002-10

Dimensions: DIN 1026-2: 2002-10

Tolerances: EN 10279: 2000

Surface condition: according to EN 10163-3: 2004, class C,

subclass 1

| Item | G | h | b | tw | tf | r | A | hi | d | Ø | emin | emax | AL | AG |

| kg/m | mm | mm | mm | mm | mm | mm2 | mm | mm | mm | mm | m2/m | m2/t | ||

| x102 | ||||||||||||||

| UPE 80* | 7.90 | 80 | 50 | 4.0 | 7.0 | 10 | 10.1 | 66 | 46 | – | – | – | 0.343 | 43.45 |

| UPE 100* | 9.82 | 100 | 55 | 4.5 | 7.5 | 10 | 12.5 | 85 | 65 | M 12 | 35 | 36 | 0.402 | 41.00 |

| UPE 120* | 12.1 | 120 | 60 | 5.0 | 8.0 | 12 | 15.4 | 104 | 80 | M 12 | 35 | 41 | 0.460 | 37.98 |

| UPE 140* | 14.5 | 140 | 65 | 5.0 | 9.0 | 12 | 18.4 | 122 | 98 | M 16 | 35 | 38 | 0.520 | 35.95 |

| UPE 160* | 17.0 | 160 | 70 | 5.5 | 9.5 | 12 | 21.7 | 141 | 117 | M 16 | 36 | 43 | 0.579 | 34.01 |

| UPE 180* | 19.7 | 180 | 75 | 5.5 | 10.5 | 12 | 25.1 | 159 | 135 | M 16 | 36 | 48 | 0.639 | 32.40 |

| UPE 200* | 22.8 | 200 | 80 | 6.0 | 11.0 | 13 | 29.0 | 178 | 152 | M 20 | 46 | 47 | 0.697 | 30.60 |

| UPE 220* | 26.6 | 220 | 85 | 6.5 | 12.0 | 13 | 33.9 | 196 | 170 | M 22 | 47 | 49 | 0.756 | 28.43 |

| UPE 240* | 30.2 | 240 | 90 | 7.0 | 12.5 | 15 | 38.5 | 215 | 185 | M 24 | 47 | 51 | 0.813 | 26.89 |

| UPE 270* | 35.2 | 270 | 95 | 7.5 | 13.5 | 15 | 44.8 | 243 | 213 | M 27 | 48 | 50 | 0.892 | 25.34 |

| UPE 300* | 44.4 | 300 | 100 | 9.5 | 15.0 | 15 | 56.6 | 270 | 240 | M 27 | 50 | 55 | 0.968 | 21.78 |

| UPE 330* | 53.2 | 330 | 105 | 11.0 | 16.0 | 18 | 67.8 | 298 | 262 | M 27 | 54 | 60 | 1.043 | 19.60 |

| UPE 360* | 61.2 | 360 | 110 | 12.0 | 17.0 | 18 | 77.9 | 326 | 290 | M 27 | 55 | 65 | 1.121 | 18.32 |

| UPE 400* | 72.2 | 400 | 115 | 13.5 | 18.0 | 18 | 91.9 | 364 | 328 | M 27 | 57 | 70 | 1.218 | 16.87 |

English

English

Spanish

Spanish French

French